Cartridge exhaust system King Tiger, fixed, 2 arms

With automatic cleaning by HiRoto® H – nozzle

Application

- for medium and heavy load jobs

- used for the most common exhausting tasks, 24-hour operation

- automatic filter cleaning

Technical specifications

- Volume rate: 3,000 m³/h

- Flow rate (arm): 2 x 1,000 m³/h

- Motor power: 2.2 kW

- Power supply: 380 – 400 V/50 Hz or 60 Hz (optional)

- Filter effectivity: ≥ 99.9 %

- Noise level: < 72 dB(A)

- Dimensions: 700 x 700 x 1,285 mm

- Weight: 155 kg

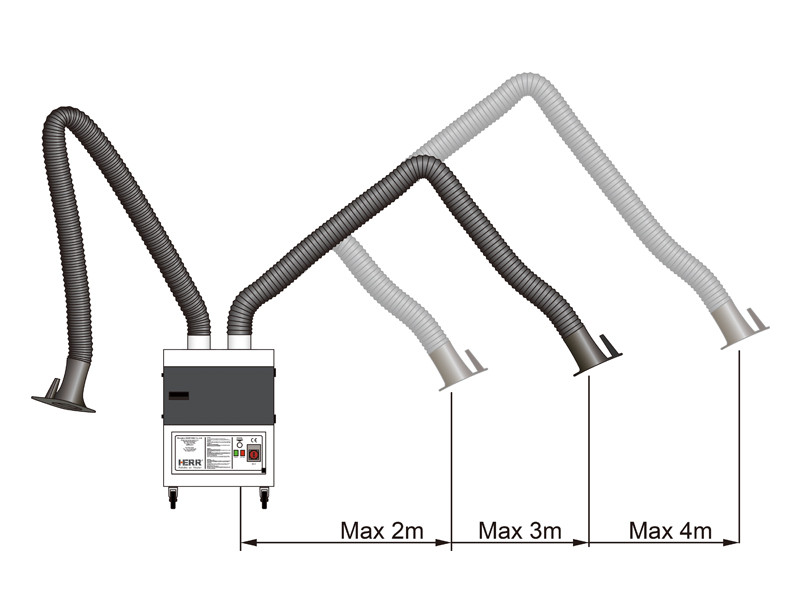

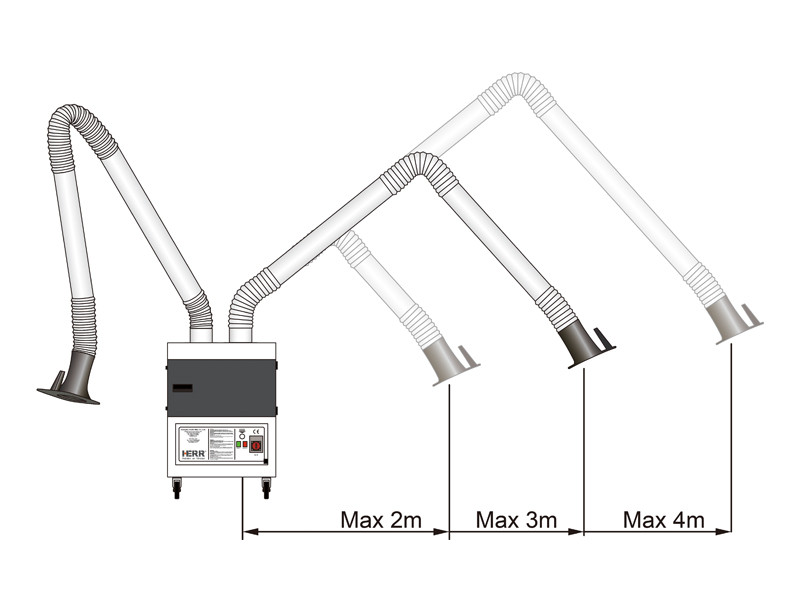

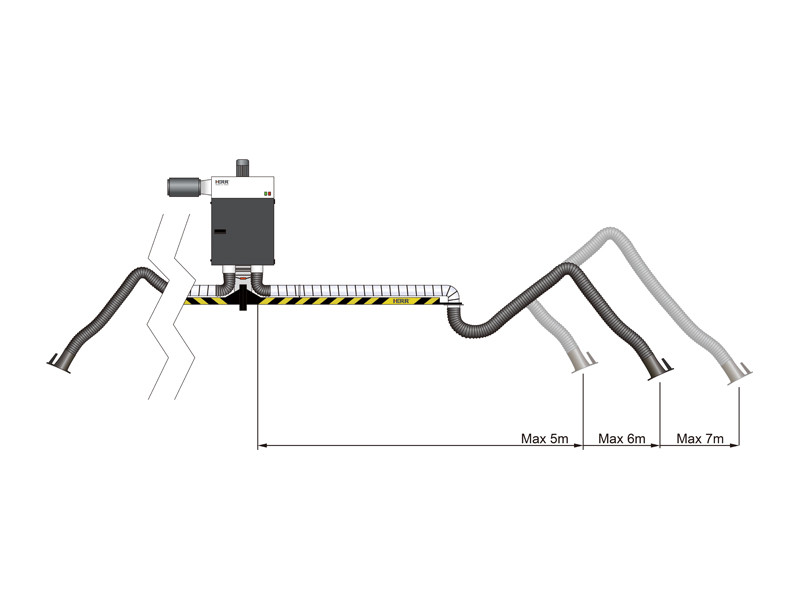

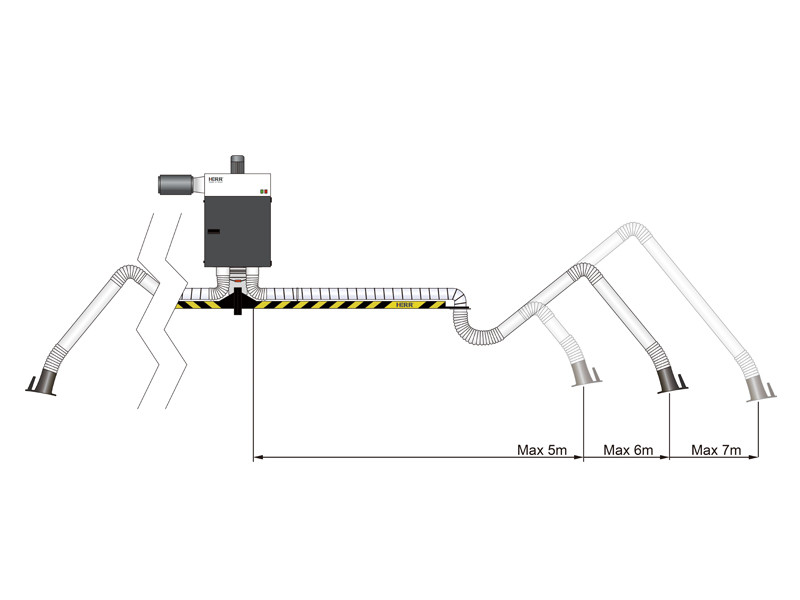

- Arm length: 8 – 11 m (with boom)

Scope of delivery

- complete machine with HISTec®-cartridge filter

- incl. 2 extraction arms and flared hoods

- individually adaptable by numerous accessories

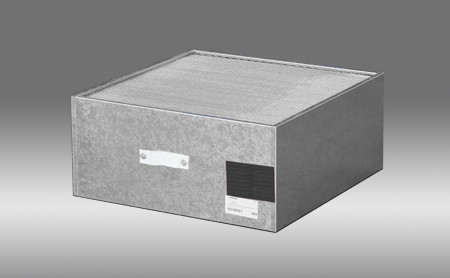

Cartridge filter KING TIGER

HERR Industry System uses a variety of filter cartridges for the purification of cutting and welding exhausts. The cartridge systems can be automatically cleaned. They incorporate the use of the HiRoto® H-type rotary backflush nozzle.

The HiRoto® H rotary back flush nozzle and the HISTec® ePTFE laminated filter cartridge are the perfect combination of a high efficiency filter cartridge and cleaning device. They can easily handle any heavy dust workload, from a variety of sources including CNC plasma cutting, and CNC laser cutting.

The filter system initiates the cleaning process when an internal pressure sensor measures a change in the pressure differential between the inside and outside of the cartridge. This instructs the system that dust has accumulated on the outside of the filter cartridge and to initiate a cleaning process. After cleaning, the dust falls to the bottom of the collection box. The filtered air is clean and can be returned inside the factory.

Cartridge exhaust syestems use the same ePTFE filter cartridge as our central exhaust systems. Filter life is upwards to 3 to 5 years.

Wall mounting creates space

Stationary filter units can be mounted directly on the wall or on support beams, leaving more free space in the immediate working environment. To ensure that the flow of work is not interrupted, a suitable height must be chosen during the assembly.

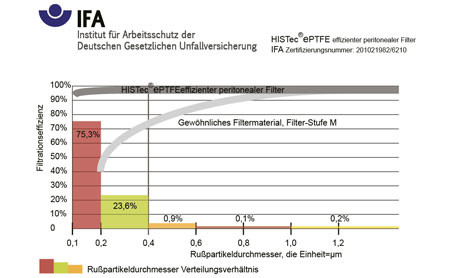

Certification by IFA

The German Institute for Occupational Safety and Health (IFA) confirmed that the HISTec® ePTFE coated cartridge filter, filter welding and cutting particles of size 0.1 microns.

The filter efficiency is up to 99.9 %.

ePTFE coating of the filter cartridges

According to the test data of the German Institute for Occupational Safety and Health IFA the collected dust particles have a diameter between 0.1 – 1.0 μm.

More than 90 % of the dusts having a diameter of less than 0.4 microns. This particles may access the lungs directly through the alveoli, penetrate into the bloodstream and cause several diseases.

Welding and cutting dusts therefore represent a major health risk. With ordinary filter material particles are filtered less than 0.4 microns inadequately. More than 90 % of the particles can exert their harmful effects despite filtration. HISTec® ePTFE cartridge filter will help to prevent your workers effectively!

HISTec® filter cartridge

The filter material of the ePTFE coated HERR filter cartridge is folded like the bellows of an accordion. The distance between the folds is consistent and is fixed by gluing of the filter in the bottom and lid. The folding angle of filter cartridge is less than 2°, thus provids an optimum of filter surface with high efficiency airflow.

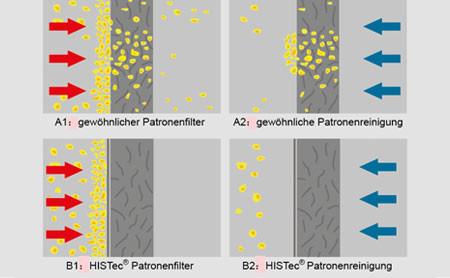

Automatic filter cleaning by HiRoto® H – nozzle

The rotating HiRoto® H – nozzle ensures the automatic cleaning of the filter cartridge.

The HiRoto® H – nozzle is the perfect complement for the ePTFE coated HISTec® cartridge filters because it allows a gentle but complete cleaning of the cartridge. In case the filter is dirty, the system starts the cleaning process automatically. According to our experience the filter exchange is needed only after 3 – 5 years!

Zubehör, Verschleißteile, Ersatzteile

HISTec® filter cartridge

- 930101 HISTec® ePTFE coated high efficiency filter cartridge

Pre-filter membrane

- 910020 Stainless steel pre-filter membrane

- 910021 Aluminium pre-filter membrane

Pre-filter

- 910010 Pre-filter, 10 pc./package

- 920005 Secondary pre-filter, 5 pc./package

Funnel-shaped hood

- 900212 Funnel-shaped exhaust hood, Ø 170 mm

Exhaust hood with light

- 900114 Trump-shaped exhaust hood with light, Ø 170 mm

Exhaust hood

- 900112 Trump-shaped exhaust hood, Ø 170 mm

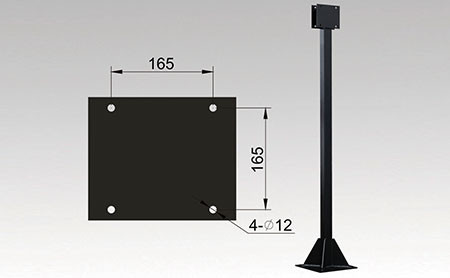

Fixed column for exhaust arm extension

- 952700 Fixed column for exhaust arm extension, height 2,900 mm

Fixed column

- 952301 Fixed column, height 2,300 mm

Fine filter

- 910100 Fine filter, main element

- 910101 Ultrafine filter, main element

Activated carbon filter

- 910201 Activated carbon filter

Exhaust arm gasket

- 900001 Exhaust arm gasket