Sliding suction channel

Application

- suitable for manual jobs and for robot systems with exhaust hood

- maximum working radius or workspace

- compatible with different suction hoods

- integrated throttle for setting the exhaust volume

Technical specifications

- Dimensions as required

- suction hood rotatable

- robust suction vehicle, optionally with rotary joint

Sliding rail extraction

A slide-rail extraction is used when the welding work require precise but linear flexible extraction. The slide-rail extraction consists of an aluminum channel with inlaid rubber lips, a sliding carriage with mounted fitting, exhaust arm and extraction hood. The channel is connected to a fan.

The sliding carriage is guided vertically or horizontally across the aluminum extraction channel. The connector is mounted between the rubber lips of the channel. By the resulting vacuum during suction the fitted in the suction rubber lips pull together. The channel is closed thereby. The connector pushes apart the rubber lips and creates a gap, thereby the polluted air is sucked through the exhaust arm into the rail channel.

The polluted air is passed through the channel and via a pipe system into a filter. The combination of linear movable carriage and a flexible exhaust arm guarantees an efficient, precise extraction along a straight line.

Parts and accessories

Funnel-shaped hood

- 900212 Funnel-shaped exhaust hood, Ø 170 mm

- 900214 Suction nozzle, funnel shape, connection 170 mm, with LED lighting

- 900222 Suction nozzle, funnel shape, metal version, connection 255 mm

Exhaust hood with light

- 900114 Trump-shaped exhaust hood with light, Ø 170 mm

Exhaust hood

- 900112 Trump-shaped exhaust hood, Ø 170 mm

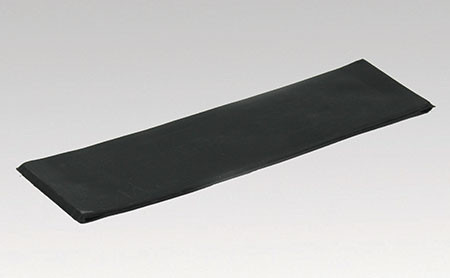

Exhaust arm gasket

- 900001 Exhaust arm gasket, Ø 170 mm

- 900003 Exhaust arm gasket, Ø 250 mm