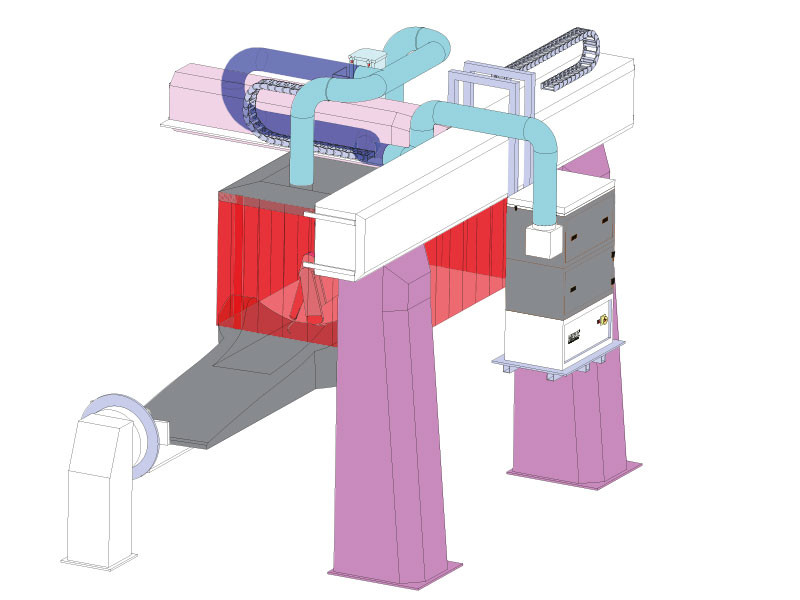

Central cartridge exhaust system – 880 series

Compact cartridge filter for central extraction and filtering

Application

- Welding robots extraction in connection with AirVent hoods

- Plasma and Oxyfuel cutting applications with low dust level

Technical specifications

- Volume flow: 3,000 m³/h

- Power consumption: 2 x 1.5 kW

- Dimensions: 1,420 x 1,810 x 700 mm

Scope of delivery

- Single complete machine (NOT suitable for outdoor installation!)

- complete with piping, depending on application

- ideal in connection with AIRVENT hood

First choice for welding robot extraction: Series 880 from HERR Industry System

The 880 series filter units are the most compact filter units from HERR Industry System.

They are ideal for robotic welding systems in combination with extraction hoods as well as lightest plasma or oxyfuel cutting applications. Series 880 filter units are designed for installation inside the workshop. They require little space due to the integrated fan.

Up to four 600 mm high HisTec® ePTFE filter cartridges with 10 m2 filter surface each are used. Cleaning is carried out with the reliable and careful HiRoto® cleaning nozzle. The filters are installed vertically or upright.

The filter is controlled by a Siemens “Logo” control system. Depending on the required cleaning volume, filter units of the 880 series are available up to 3.000 m3/h.

Series 880 filter units are often the first choice for extraction at robot workstations in combination with an extraction hood

Frequency converter

Frequency converters are used especially in the extraction of several welding workstations. They adjust the airflow to the workload. Through sensors, the filter system recognizes the required air pressure.

The frequency converter will adjust the fan speed to the conditions. This increases the life of the filter cartridges, reduces the need for exhaust air and helps to reduce the power consumption. The additional cost of the frequency converter pays for itself in a short time.

Fire protection

HERR Industry system filter systems are among the safest filtering systems on the market: pre-filter chamber, vertically built filter cartridges, special routing of the air in the filter chamber, complete cleaning of the filter cartridges at the end of the working day and a special design of the cover of the dust box effectively prevent the occurrence of filter fires.

Optional additional options for firefighting are available: sensors for temperature-sparks monitoring, CO2, water foam deletion, automatic partitioning of the filter.

Fan

The selection of a suitable fan not only saves energy, it is also important for the life of the filter cartridges.

With increasing life span of the filter the air resistance of the filter cartridge increases slightly but steadily. The fan must be able to compensate this justice. This is best accomplished with a control via frequency converters.

Convenient and safe dust disposal

The dust is collected in an area under the filter in a dust box. During operation, the container is pneumatically pressed against the filter. To empty it can be released and moved out on rollers.

Cheap PVC waste bags minimize contact to dust and can be easily removed and replaced. The container should be emptied at least once daily. Optionally, a emptying in barrels or with the rack locks are available at extra cost.

Intelligent control

The central suction systems from HERR Industry System using Siemens control and a specially developed software from HERR Industry System.

All important functions and messages of the control are displayed on a LCD screen. Important areas are protected with a password to prevent accidental deletion or change of parameters. The comfortable control simplifies operation and provides important instructions for maintenance and problem diagnosis.

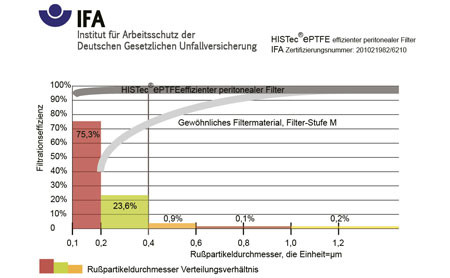

Certification by IFA

The German Institute for Occupational Safety and Health (IFA) confirmed that the HISTec® ePTFE coated cartridge filter, filter welding and cutting particles of size 0.1 microns.

The filter efficiency is up to 99.9 %.

ePTFE coating of the filter cartridges

According to the test data of the German Institute for Occupational Safety and Health IFA the collected dust particles have a diameter between 0.1 – 1.0 μm.

More than 90 % of the dusts having a diameter of less than 0.4 microns. This particles may access the lungs directly through the alveoli, penetrate into the bloodstream and cause several diseases.

Welding and cutting dusts therefore represent a major health risk. With ordinary filter material particles are filtered less than 0.4 microns inadequately. More than 90 % of the particles can exert their harmful effects despite filtration. HISTec® ePTFE cartridge filter will help to prevent your workers effectively!

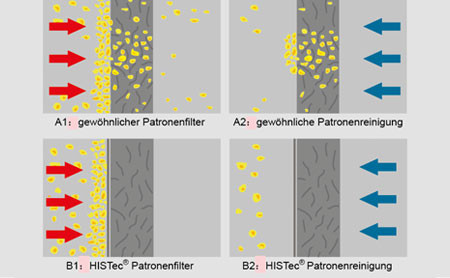

HISTec® filter cartridge

The filter material of the ePTFE coated HERR Industry System filter cartridge is folded like the bellows of an accordion. The distance between the folds is consistent and is fixed by gluing of the filter in the bottom and lid. The folding angle of filter cartridge is less than 2°, thus provids an optimum of filter surface with high efficiency airflow.

Automatic filter cleaning by HiRoto® H-nozzle

The rotating HiRoto® H-nozzle ensures the automatic cleaning of the filter cartridge.

The HiRoto® H-nozzle is the perfect complement for the ePTFE coated HISTec® cartridge filters because it allows a gentle but complete cleaning of the cartridge. In case the filter is dirty, the system starts the cleaning process automatically. According to our experience the filter exchange is needed only after 3 – 5 years!