HOFE Double – Mechanical oil mist filtration

Suction device for oil mists with 2 electrostatic filters

HERR Industry System oil mist filters focus on removing oils and contaminants from the air in the work place environment to protect the health of employees.

HERR Industry System oil mist filter systems are divided into two classes, mechanical and electrostatic filtration systems. These two types are best way to deal with water-based or oil-based exhausts. For exhausts of varying oil content or composition, selecting the correct filters is important. Mechanical and electrostatic filters are suited to different concentrations and conditions of oil mist.

HERR Industry System oil mist filter systems have modular designs that allow for rapid expansion, while the controlling costs at a minimum.

Technical specifications HOFE2000D

- Extraction volume: 2,000 m3/h

- Motor power: 0.75 kW

- Power supply: 380 – 400 V/50 Hz

- Filter effectivity: ≥ 95 %

- Noise level: < 68 dB (A)

- Dimensions: 1,624 x 652 x 682 mm

- Weight: 175 kg

Technical specifications HOFE5000D

- Extraction volume: 5,000 m3/h

- Motor power: 1.5 kW

- Power supply: 380 – 400 V/50 Hz

- Filter effectivity: ≥ 95 %

- Noise level: < 68 dB (A)

- Dimensions: 1.624 x 1.100 x 700 mm

- Weight: 285 kg

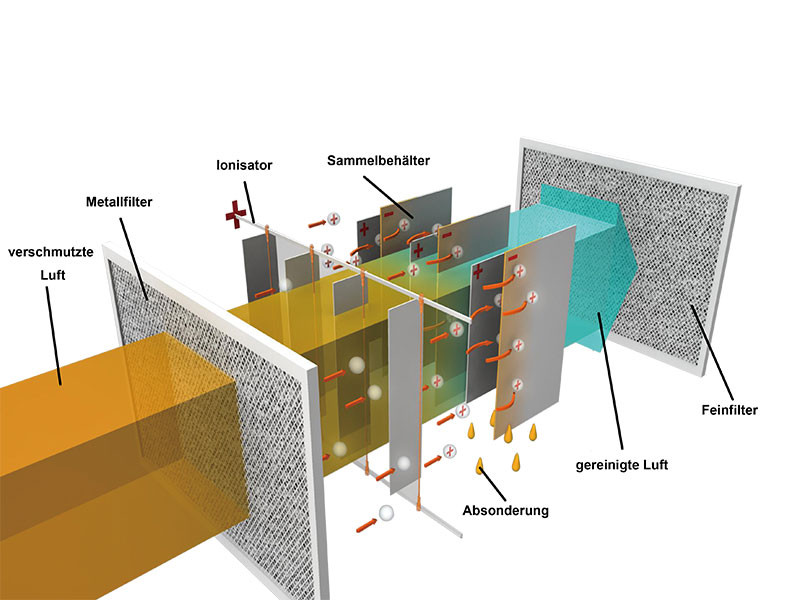

Optimal for high oil amount: electrostatic oil mist filter systems with backup

HOFE electrostatic filter systems are recommended for higher levels of oil in the oil mist or fumes. The compared to mechanical systems higher investment costs pay for themselves due to lower maintenance costs in the shortest possible time. The power is adjustable between 4,000 – 12,000 V and therefore adaptable to the local conditions. Our service technicians are happy to help you find the right setting for your application.

For higher air volume and concentrations of oil smoke and polluted air, filter systems are type “D” will be used, i.e. a second filter is fitted in row, which increases the filter efficiency and increases the safety and purity of the air.

The electrostatic filter systems, as well as mechanical filter systems, to be installed as individual units or as a central filter system in the composite. On a single filter up to five processing centers can be connected.

If more suction volume is necessary, additional filters could be added to the central filter system. So a simple extension of the central filter system to adapt to future needs is possible. Central filter systems also effectively reduce operating and maintenance costs.