Central cartridge exhaust & filtration systems

Tailored to your needs

Central extraction and filter systems were developed by HERR Industry System with the focus on the extraction of large amounts of dust particiles in the nano range.

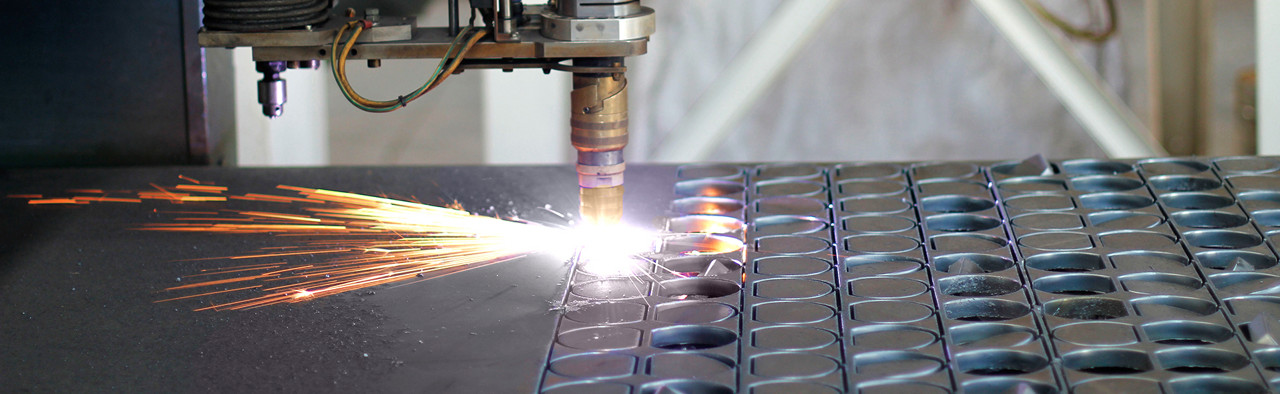

The integrated spark protection system prevents the filter cartridges during oxy-fuel, plasma or laser cutting. The systems are also available in explosion-proof versions. All systems are modular, freely configurable and expandable.

-

Central cartidge exhaust system – 600 series

for the central suction and filtering of dust and smoke!DetailsApplications

- Workshop extraction

- Central extraction of several workstations and welding booths

- Extraction of plasma cutting tables

- Extraction of welding hoods for robots

Technical specifications

- Flow rate: 3,000 – 12,000 m³/h

- Power consumption: 3.0 kW – 15 kW

- useful as combined devices

Scope of delivery

Depending on the application:- Single complete machine or in combination with f.e. cutting table (NOT suitable for outdoor installation!)

- complete with piping, depending on application

- designed according to your individual needs

-

Central cartridge exhaust system – 610 series

for the central suction and filtering of dust and smoke!DetailsApplication

- for strongest extraction and filtering tasks

- Installation for indoor or outdoor use

- Central extraction of several workstations and welding booths

- Extraction of cutting tables

- Extraction of welding hoods for robots

Technical specifications

- Flow rate: 4,000 – 36.000 m³/h

- Power consumption: 5.5 kW – 37 kW

- useful as combined devices

Scope of delivery

Depending on the application:- Single complete machine or in combination with f.e. cutting table

- complete with piping, depending on application

- designed according to your individual needs

-

Central cartridge exhaust system – 880 series

Compact cartridge filter for central extraction and filteringDetailsApplication

- Welding robots extraction in connection with AirVent hoods

- Plasma and Oxyfuel cutting applications with low dust level

Technical specifications

- Volume flow: 3,000 m³/h

- Power consumption: 2 x 1.5 kW

- Dimensions: 1,420 x 1,810 x 700 mm

Scope of delivery

- Single complete machine (NOT suitable for outdoor installation!)

- complete with piping, depending on application

- ideal in connection with AIRVENT hood